Unlocking Reserves: Introduction to Thermal Recovery of Thick Oil

The world’s insatiable appetite for energy has propelled the oil and gas industry into a constant quest for innovative techniques to maximize the extraction of hydrocarbon reserves. As conventional oil fields mature and easily accessible resources diminish, attention has turned to unconventional reservoirs, including those with thick or heavy crude oil. Among the methods employed to unlock the potential of these viscous reserves, thermal recovery techniques have emerged as a transformative solution. This essay delves into the introduction of thermal recovery for thick oil, highlighting its significance, mechanisms, and impact on the energy landscape.

The Challenge of Thick Oil Reservoirs:

Thick or heavy crude oil, characterized by its high viscosity and density, poses a distinct challenge to the traditional methods of oil recovery. Unlike the easily flowing light crude, which can be extracted through primary methods, thick oil requires specialized techniques to overcome its inherent resistance to flow. These unconventional reservoirs often represent vast untapped resources that are not only valuable for meeting energy demands but also for diversifying the sources of hydrocarbons and ensuring energy security.

Thermal Recovery: A Paradigm Shift:

Thermal recovery techniques have revolutionized the approach to thick oil reservoirs, presenting a paradigm shift in oil recovery methods. Unlike primary methods that rely on the natural pressure of the reservoir to push oil to the surface, thermal recovery methods introduce external energy to reduce the viscosity of the oil and enhance its flow properties. By doing so, these techniques effectively transform the economic viability of recovering oil from unconventional reservoirs.

Steam Assisted Gravity Drainage (SAGD):

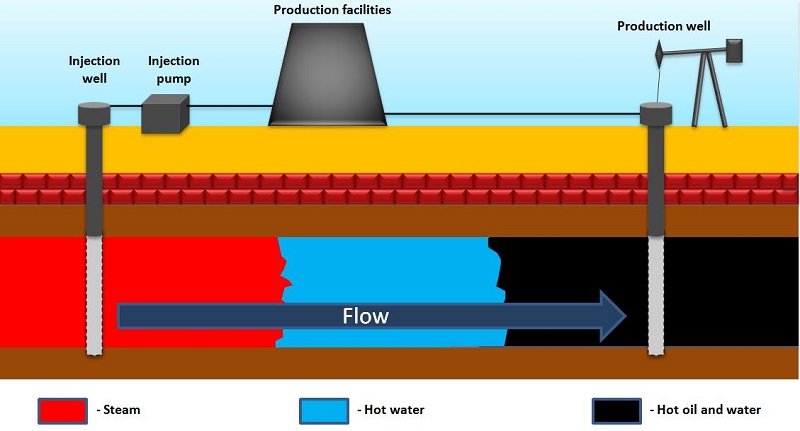

Among the pioneering thermal recovery techniques is Steam Assisted Gravity Drainage (SAGD). This method involves injecting steam into the reservoir to heat the thick oil, reducing its viscosity and enabling it to flow more freely. The heated oil drains through gravity into production wells, allowing for efficient extraction. SAGD has gained prominence for its success in extracting bitumen from oil sands in Canada, unlocking immense reserves that were previously considered challenging to recover.

Cyclic Steam Stimulation (CSS):

Cyclic Steam Stimulation, also known as “huff and puff,” is another thermal recovery technique employed in thick oil reservoirs. In CSS, steam is injected into the reservoir to heat the oil, facilitating its flow to the wellbore. Once the oil production rate declines, the injection of steam is halted, allowing the reservoir to cool down. Subsequently, the well is converted to a production mode again, effectively “puffing” the oil to the surface. This cyclic process continues, optimizing the extraction of oil.

Toe-to-Heel Air Injection (THAI):

Toe-to-Heel Air Injection (THAI) is an innovative thermal recovery technique designed to recover heavy oil and bitumen in an in-situ combustion process. In THAI, air is injected into the reservoir through a horizontal well, igniting the oil in place. The combustion front advances through the reservoir, creating a “toe” of burned oil and a “heel” of unburned oil. The heat generated by combustion reduces the viscosity of the oil, making it easier to produce. THAI offers the advantage of in-situ upgrading of heavy oil, converting it into lighter and more valuable products.

Impact on Energy Landscape:

The introduction of thermal recovery techniques has had a profound impact on the global energy landscape. These methods have unlocked previously untapped resources, contributing to the diversification of energy supplies and enhancing energy security. As conventional oil reserves decline, the ability to extract oil from unconventional sources becomes increasingly vital to meet growing energy demands.

Furthermore, thermal recovery methods align with sustainability goals by optimizing resource utilization. Recovering oil from unconventional reservoirs reduces the need for extensive surface mining and extraction, which can have significant environmental impacts. Additionally, thermal recovery can potentially lead to reductions in greenhouse gas emissions by converting heavy oil into lighter products with lower emissions profiles.

Challenges and Considerations:

While thermal recovery techniques hold immense promise, they are not without challenges and considerations. The energy required to generate steam or initiate combustion can be substantial, making the process energy-intensive. Innovations in energy-efficient technologies and renewable energy integration are crucial to mitigating this challenge. Moreover, the management of produced water, which may be contaminated due to thermal operations, requires careful attention to environmental stewardship.

Conclusion:

In conclusion, the introduction of thermal recovery techniques has transformed the way the oil and gas industry approaches thick oil reservoirs. By harnessing external energy to reduce viscosity and enhance flow properties, these methods have opened the doors to vast reserves that were once deemed economically unviable. Steam Assisted Gravity Drainage (SAGD), Cyclic Steam Stimulation (CSS), and Toe-to-Heel Air Injection (THAI) are leading the way in reshaping the energy landscape and ensuring a more sustainable future for hydrocarbon extraction. As the world navigates the complex interplay between energy demand, environmental responsibility, and technological innovation, thermal recovery methods stand as a beacon of ingenuity, unlocking the potential of thick oil reserves while aligning with global sustainability goals.

By Sun

By Sun