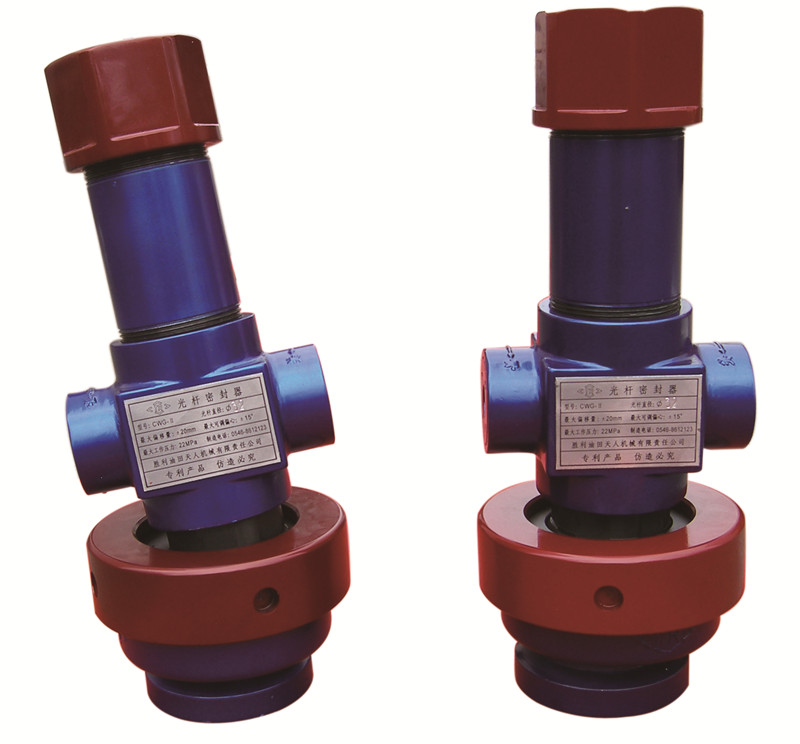

ShengjiPetro polished rod stuffing box is a new patent product developed by ShengjiPetro oil and gas stuffing box manufacturer.

Automatic axial self-aligning,

Radial offset, simple maintenance,

Longer service life, antitheft and increasing production.

The unique superiority will be highlighted if ShengjiPetro oilfield stuffing box is applied in thickened oil well, polymer injection well, high water cut well and with deep pumping.

The oilfield stuffing box on pumping well abrades frequently and loses sealing effect due to the eccentric wear and reciprocation of polished rod, which badly reduces service life and results oil leak. The well is regularly shutdown to change stuffing box. The cost, management difficulty and work strength of oil workers increase for this reason. In the meantime, it causes surface pollution and crude oil loss.

ShengjiPetro the fine tuning long-term polished rod stuffing box is our company’s new type patent product. The product is easy to install and convenient to maintain with simple structure, and it is a polished rod stuffing box which doesn’t need to change the sealing parts frequently through several micro adjustment,to guarantee the sealing effect. The chosen sealing part is cone sealing element which is made of special formula. ShengjiPetro the fine tuning long-term polished rod stuffing box is made of three level seals. Sealing part Ι was design for helping change sealing part ΙΙ of failure that due to abrasion. While ShengjiPetro polished rod stuffing box normal running, the bolts on both side are in highest position,and sealing part Ι is in free state. It takes effect while changing sealing part ΙΙ. Sealing part ΙΙ take seal effect is effective in sealing throughout the polished rod’s moving movement,it can be adjusted by fine tuning structure, and compensate the element abrasion continuously, to keep good seal. Sealing part ΙΙΙ is to prevent the grease spill from the stuffing box,it prevent sand from dropping into the seal and hurting the polished rod and the sealing parts, it doesn’t bear pressure.

| Name

Parameters | CWG-series polished rod stuffing box | Remarks | |

| Model | CWG25~CWG38 | ||

| Max. Diameter (mm) | φ180 |

| |

| Max. Height(mm) | 460 |

| |

| Working pressure(MPa) | 21 |

| |

| Joint mode | Clamp type, coupling type | ||

| Suitable polished rod diameter(mm) | φ25~φ38 | Customizable | |

| Max. aligning and deviation adjustment | Axial ±10°, radial ±20mm | ||

| Weight(kg) | 25 | Standard: SY/T5029-2013 | |

| Name Parameters | Trimming Long-Act polished rod stuffing box |

| Working pressure(MPa) | 25 |

| Suitable polished rod diameter(mm) | 25~38 |

| Dimension | 190*190*400mm |

| Weight(kg) | 18.6 |

| Bottom connection | Clamp type, thread type |

1). Obtain the utility model patent, the patent number is ZL2005 2 0087377.1,ZL2006 2 0085213X.

2). The sealing part is consist of grade Ι,Ⅱ,Ⅲ.

3). Convenient maintenance, compact structure and easy to operate.

4). Long lifetime of the stuffing box.

5).Deviation adjustment and anti-eccentric worn: Axial self-aligning, Radial offset

6). Simple maintenance and longer service life

7). Combined type stuffing has more reliable seal effect

8). Auxiliary function:extend service life of stuffing, and in some degree optimize the working condition of polished rod.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.