Oil and Gas Separation Technology: Enhancing Efficiency in the Energy Industry

The oil and gas industry stands as a cornerstone of modern civilization, providing the fuels that power our transportation, heat our homes, and drive industrial processes. The extraction and processing of crude oil and natural gas involve intricate procedures, with one of the critical steps being the separation of oil, gas, and water. Oil and gas separation technology plays a pivotal role in optimizing production efficiency, ensuring product quality, and minimizing environmental impact within the oil and gas field. This essay delves into the evolution, significance, and advancements of oil and gas separation technology, shedding light on its role in the energy sector.

Evolution and Importance:

The separation of oil, gas, and water from the reservoir fluids is an indispensable process in the production of hydrocarbons. In the early days of the oil industry, separation methods were rudimentary, often relying on gravity to allow the different components to naturally segregate. However, as demand for oil and gas increased, so did the need for more efficient and reliable separation technologies.

The significance of effective separation lies in its ability to enhance operational efficiency and product quality. Efficient separation ensures that oil and gas are processed with minimal impurities, resulting in higher market value. Moreover, it aids in the safe and environmentally responsible management of produced water, which can contain contaminants that are harmful to ecosystems if not properly treated.

Conventional Separation Techniques:

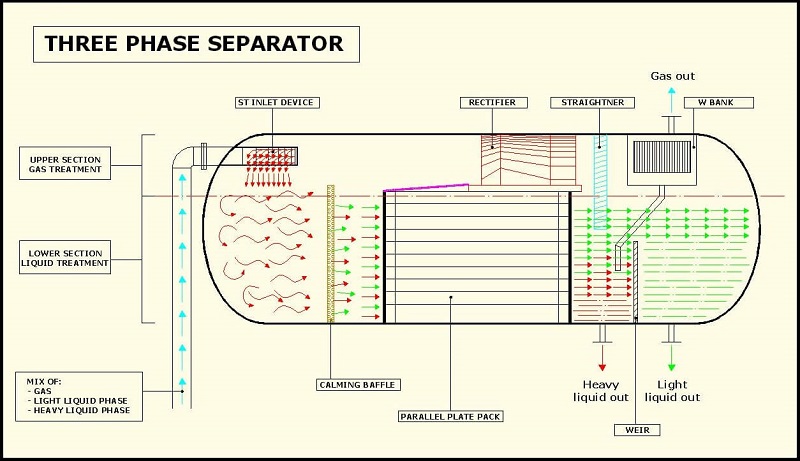

Historically, the primary separation method used in the oil and gas industry has been gravity-based separation. This involves allowing the reservoir fluids to settle in a vessel, where the lighter gases rise to the top, the oil accumulates in the middle, and the water settles at the bottom. While this method is simple and cost-effective, it has limitations in terms of its ability to achieve optimal separation efficiency, especially when dealing with complex reservoir fluids.

Advanced Separation Technologies:

The demand for increased efficiency and the challenges posed by unconventional reservoirs have driven the development of advanced separation technologies. These technologies leverage a combination of mechanical, chemical, and physical processes to achieve superior separation results.

1. Cyclonic Separation: Cyclonic separators use the principle of centrifugal force to separate oil, gas, and water. The fluids are subjected to a swirling motion, which causes the different components to segregate based on their densities. This method is highly effective and is often used in offshore platforms and remote locations.

2. Hydrocyclones: Hydrocyclones are specialized devices that use centrifugal forces to separate fluids of different densities. They find applications in both upstream and downstream processes, such as separating wellhead fluids, desanding produced water, and enhancing the efficiency of downstream refining processes.

3. Membrane Separation: Membrane technologies, such as ultrafiltration and reverse osmosis, have gained prominence for their ability to selectively separate oil, gas, and water based on molecular size and properties. These technologies are particularly useful in treating produced water and in enhancing the quality of natural gas streams.

4. Electrostatic Coalescers: Electrostatic coalescers utilize electric fields to induce the coalescence of small droplets, thereby facilitating the separation of oil and water. This technology is often employed in refining and petrochemical processes to remove impurities from feedstock streams.

5. Smart Separation: The advent of digitalization and the Internet of Things (IoT) has enabled the development of “smart” separation technologies. These systems use sensors and real-time data analysis to optimize the separation process, ensuring the most efficient use of resources and minimizing operational disruptions.

Environmental and Economic Implications:

**Reducing Emissions and Pollution:**

One of the primary environmental benefits of advanced separation technologies is their capacity to reduce emissions and pollution. During the extraction and processing of crude oil and natural gas, significant amounts of associated gases are produced. If left untreated, these gases, including methane, a potent greenhouse gas, can be released into the atmosphere, contributing to climate change and air pollution. By employing efficient separation technologies, these gases can be captured and properly processed, reducing emissions and minimizing their environmental impact.

Furthermore, separation technologies help remove harmful pollutants from produced water before it is discharged or reused. Contaminants such as heavy metals, organic compounds, and suspended solids can have detrimental effects on aquatic ecosystems if released without proper treatment. By ensuring effective separation, the oil and gas industry can mitigate the negative impacts of produced water discharges, protecting water quality and aquatic life.

**Resource Conservation:**

Oil and gas separation technologies also contribute to resource conservation, which is a key tenet of environmental protection. When extraction and separation processes are inefficient, a significant portion of valuable hydrocarbons can be lost as flaring or unprocessed gas. These losses not only reduce the economic viability of operations but also lead to unnecessary emissions and resource wastage. By utilizing advanced separation techniques, the industry can maximize the recovery of valuable hydrocarbons, minimizing waste and optimizing resource utilization.

**Mitigating Accidental Spills:**

Another aspect of environmental protection involves mitigating the risk of accidental spills. Effective separation technologies ensure that hydrocarbons are properly contained and transported without mixing with water or other contaminants. In the event of a spill, the ability to separate oil, gas, and water efficiently can limit the extent of environmental damage, preventing the spread of pollutants and minimizing harm to ecosystems.

**Regulatory Compliance:**

Governments and regulatory bodies worldwide are increasingly imposing stricter environmental regulations on the oil and gas industry. These regulations often require operators to adhere to specific standards for emissions, waste disposal, and water quality. Utilizing advanced separation technologies enables companies to meet and exceed these regulatory requirements, demonstrating a commitment to environmental responsibility and avoiding potential fines or legal actions.

**Public Perception and Social Responsibility:**

The public’s perception of the oil and gas industry has evolved to include a strong emphasis on environmental responsibility. Companies that invest in and implement advanced separation technologies send a clear message to stakeholders, investors, and the general public that they take environmental protection seriously. This can enhance a company’s reputation, build trust, and foster positive relationships with local communities, regulators, and environmental organizations.

**Continued Research and Development:**

To ensure ongoing environmental protection, the oil and gas industry must continue to invest in research and development aimed at improving separation technologies. This includes enhancing the efficiency of existing processes, developing new methods for reducing emissions, and finding innovative ways to manage produced water sustainably. By collaborating with researchers, engineers, and environmental experts, the industry can drive innovation that further minimizes its ecological footprint.

Conclusion:

Oil and gas separation technology has evolved significantly from its early days of gravity-based separation. The advancement of separation techniques, such as cyclonic separation, hydrocyclones, membrane separation, electrostatic coalescers, and smart separation, has revolutionized the way the industry processes hydrocarbons. These technologies enhance production efficiency, product quality, and environmental responsibility, reflecting the industry’s commitment to sustainable practices. As the global demand for energy continues to rise, the ongoing development of oil and gas separation technology remains paramount in ensuring the responsible and efficient extraction of hydrocarbon resources.

By Sun

By Sun