Over the years, ShengjiPetro has been continuously committed to the technical research of automatic workover equipment and mastered a series of core technologies with independent intellectual property rights, which can meet the requirements of the oilfield for the upgrading of workover equipment, replacing people with machines, comprehensively reduce the labor intensity of workers, improve the working environment and effectively reduce safety risks.

Can be used together with various workover rigs and hoists to realize one driller’s operation and unmanned operation at the wellhead.

The equipment has the functions of automatic tripping, conveying and arrangement of tubing, tubing length measurement, well fluid splash prevention, etc.

The optional multifunctional elevator can also realize the functions of sand washing, drilling, grinding and milling.

Improves the operation safety, reduces the labor intensity

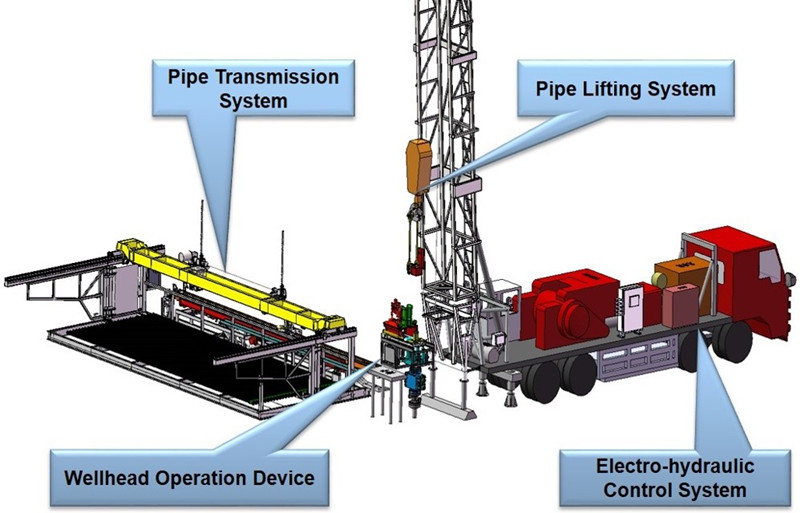

The automatic operation equipment for minor workover is mainly composed of wellhead operation device, hydraulic elevator, pipe and rod transmission and arrangement device and electro-hydraulic control system. Each part of the device has different structural forms, and can be selected arbitrarily for personalized configuration according to the needs of users.

1). Device introduction

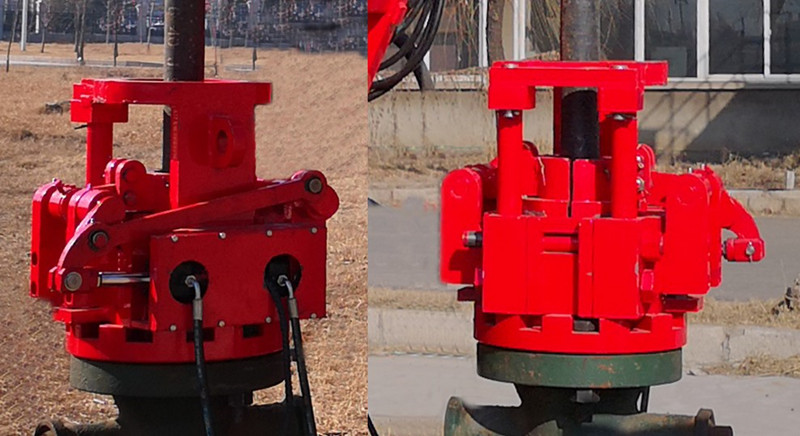

The device adopts the structural form of dispersing the functional modules and integrated installation on the workover rig: with the hydraulic tong, manipulator and anti splash snap device set on the derrick of the workover rig, which can expand and rotate, and the safety slip is installed above the BOP.

2). Device features

The device only needs to install safety slips, which realizes rapid installation and migration and shortens the auxiliary working time. The device has the function of moving back and forth, left and right, which is convenient to align the wellhead. The height of the hydraulic tong is adjustable and can adapt to the wellhead with different heights. Hoisting equipment and special transport vehicles are not required for the installation and removal of the device.

1). Device introduction

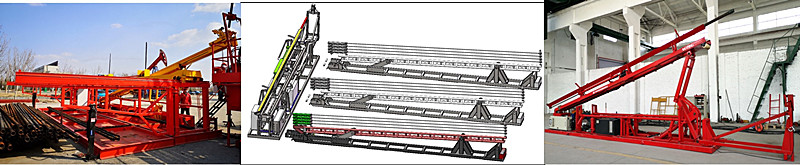

The pipe and rod transportation and arrangement device has the functions of automatic delivery, arrangement and length measurement of tubing, etc.

Applicable pipe string:ID Φ60-114mm,L 8-9.7m,Pipe string weight:300 Kg

2).Main model

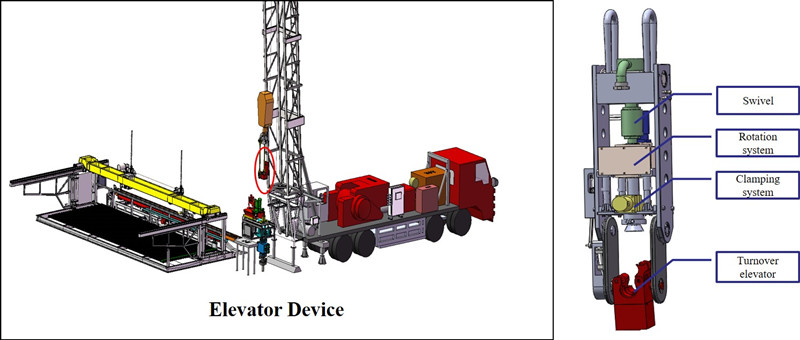

In addition to its main function of suspending the pipe string, it also has the functions of automatic tubing mouth match, make-up and break-out, and is also equipped with a guide device bearing reverse torque, which can realize the functions of automatic well washing, sand flushing, drilling, grinding and milling.

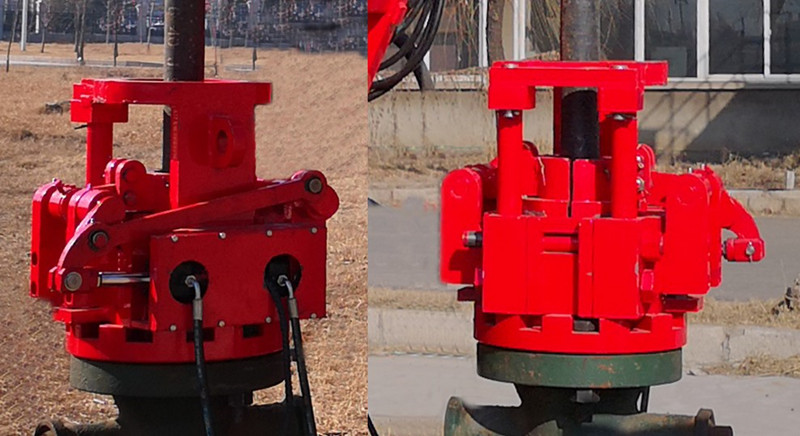

Main function: connect to the wellhead flange and clamp the pipe string. Slip teeth are common with other manufacturers for easy replacement. The hydraulic cylinder is clamped and the pipe string is forced to be centered. The clamping is reliable and convenient for automatic operation. Open and close state detection, and then realize safety interlock with other equipment.

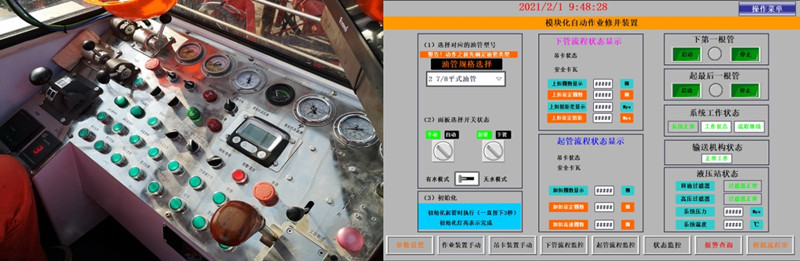

1)Electric control system

The main electric control box can be installed on the operation vehicle or integrated into the modular wellhead operation device. The make-up torque of various oil pipes is set on the touch screen to realize automatic make-up and break-down. Equipped with video monitoring, process prompt, safety alarm and etc. The control system has perfect action interlocking function to ensure the safety and reliability of workover operation process. All of electric cabinet, sensor, connector meet the requirement of Explosion proof on filed.

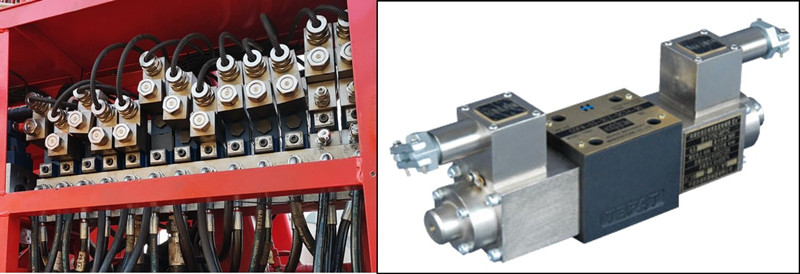

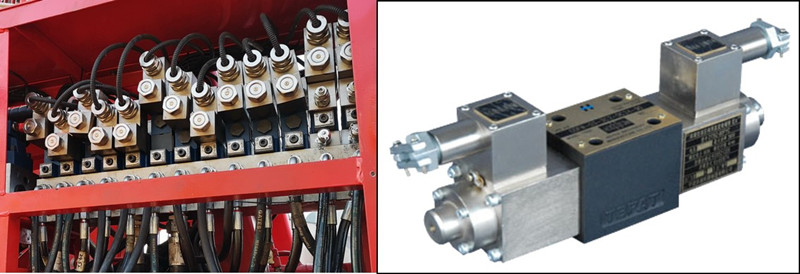

2). Hydraulic system

The hydraulic system includes hydraulic source, wellhead automatic operation device control valve group, hydraulic elevator and hydraulic slip valve group, conveyor control valve group and pipeline, etc.

Equipped with the best explosion-proof solenoid valve of domestic, which meets the explosion-proof requirements of the field.

The hydraulic source can be integrated into the conveyor or the workover rig hydraulic source can be used.

With heating and cooling functions to provide a stable power source for the normal operation of automation equipment.

The pipeline adopts quick change connector, which is convenient and fast to connect.

| Description | Parameters |

| Rated workload | 400KN、600KN |

| Tubing size | 2 3/8NU、2 3/8EU、2 7/8NU、27/8EU、3 1/2NU、 3 1/2EU、4 1/2NU(VIT) |

| Work Efficiency | 35 joints/h |

| Tubing delivery speed | 60 joints/h |

| Rotating speed | 10-60r/min |

| withstand reverse torque | 6000N.m |

| Water cycling pressure | 35MPa |

| HP | 30KW |

Model: vehicle mounted wellhead operation device + hydraulic slip + hydraulic turnover elevator + Electromagnetic adsorption pipe rod conveying and discharging device + electro-hydraulic control system (integrated on the vehicle).

Supporting workover equipment: workover rig (60t Non guy rope).

Since March 2021, the equipment has been used in Shengli Oilfield, with about 8000 meters of tubing been operated and operation efficiency reach to 40 pieces / hour.

The vehicle mounted wellhead operation device does not need to be installed, which greatly reduces the operation preparation time, and the conversion between automatic operation and manual operation is very convenient.

One driller can complete all automatic operations.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.