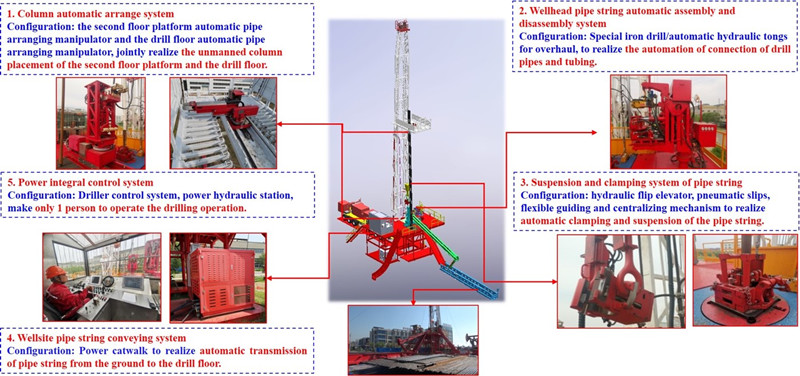

ShengjiPetro began to develop major automatic workover rig since 2015. It has experienced the 1st generation of full hydraulic power and the 2nd generation of electro-hydraulic combination power. After years of continuous improvement and technical upgrading, all key technologies of automation hardware and software have been independently developed, and more than 10 utility models and invention patents have been applied. Major operation automatic workover rigs are gradually promoted and applied, which can provide a series of technical solutions for the transformation of old models and supporting new models.

Reduce labor intensity by 80%.

Cancel the operator on the second floor and reduce the number of operators.

Reduce the risk of personal injury, reduce industrial accidents.

ShengjiPetro has been committed to the research of automatic workover technology for many years, and has a perfect of automatic workover technology development, production and manufacturing system. In recent years, a whole set of automation technology has been formed in the automation and intelligent development of automatic workover equipment. Through the application of module design, servo drive, integrated control, electro-hydraulic compound drive and other technologies, the supporting products suitable for various types of workover equipment have been developed to meet the needs of oilfield workover equipment upgrading.

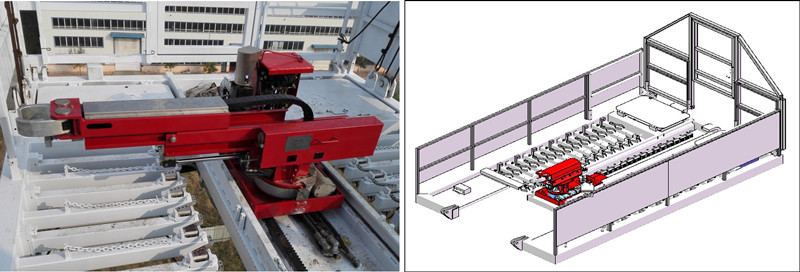

Second floor platform automatic pipe arranging manipulator replace the derrick worker on the second-story platform, it is to use fully automatic grabbing and arrange pipe string erection operations, realizing unattended operation on the second-story platform.

Drill floor automatic pipe arranging manipulator can replaced workers to complete the placement of the column on the drill floor surface, and connect single joint, thread connection, etc., to achieve unmanned operation of the drill floor for major workover operations.

2.Wellhead string automatic make-up and break-down system

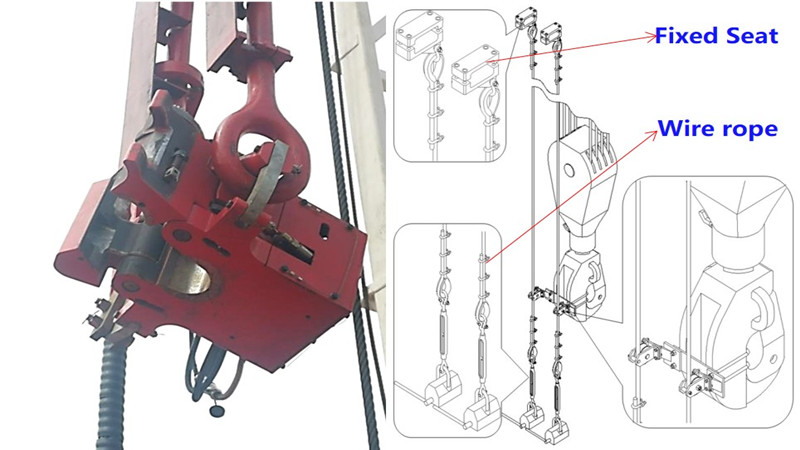

Two kinds of automatic make-up and break-down equipment with different structural forms and different characteristics replace the manual push-pull operation of hydraulic tong.

1). Automatic hydraulic tong

It is applicable to a wide range of pipe diameters and can realize up to 5 1 / 2 "casing up and down.

The tong body floats and hangs, and the tong mouth automatically aligns the center of the pipe string, which can be clamped reliably without damaging the surface of the pipe body.

Equipped with jaw slip protection control system to ensure the safe operation of automatic hydraulic tong.

The lifting stroke is large, which can adapt to the coupling height of two operation modes with slip and without slip.

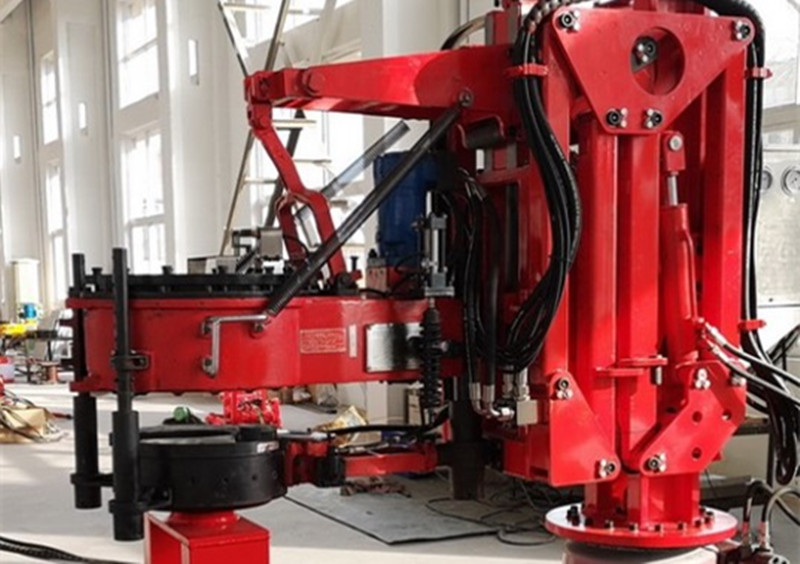

2).Iron drillers

The original integrated structure of hydraulic tong and punching tong can meet the thread up and down of tubing / drill pipe at the same time. The tong head has floating function, which can automatically compensate the center deviation between the pipe string and the jaw and reduce the damage when the tong teeth clamp the pipe body. The torque can be accurately controlled and set, and the make-up torque of pipe string meets the requirements of API. When in standby, it can rotate and give way as a whole to provide more active operation space for the drill floor. The tong head can be deflected to meet the make-up & break-down of mouse hole string.

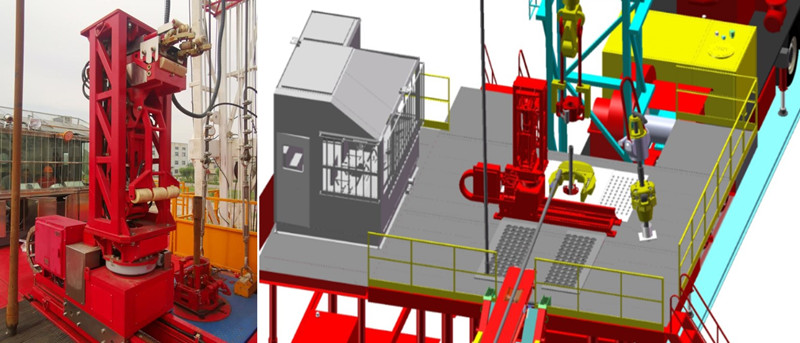

1). Hydraulic flip elevator

Instead of the traditional mechanical elevator, the hydraulic drive valve is opened and closed, and the elevator is deflected and overturned, so there is no need to lift the elevator manually.

2). Pneumatic Slip

Replace the manual lifting elevator to automatically clamp and fix the pipe string.

Main function: replace the field worker to lift the pipe string and realize the automatic transportation of the pipe string from the ground to the drill floor.

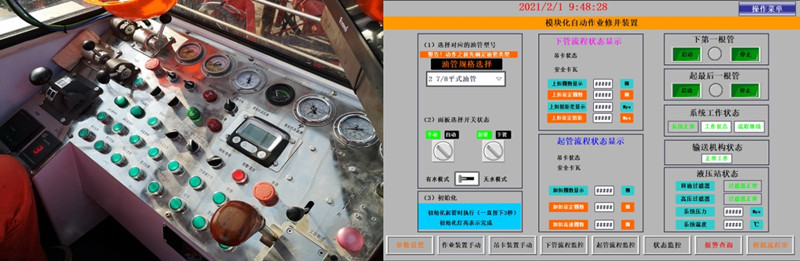

1).Electrical control system

It adopts programmable integrated control and industrial network communication to realize centralized control, process management and status monitoring of all automation equipment.

2). Hydraulic control system

The hydraulic station provides hydraulic power for automatic loading and unloading hydraulic clamps, hydraulic elevators, pipe string conveyors, drill floor manipulators and other equipment.

In July 2020, the new XJ450 overhaul operation automation equipment (main configuration: two-story platform manipulator, drill floor manipulator, elevator, slips, iron drill for workover, pipe string conveyor, power centralized control system, etc.) entered the site During the construction operation, the whole set of equipment is running stably, and one person can complete the operation when starting and drilling, realizing the unmanned operation of the wellhead and the second deck, effectively reducing labor intensity, and realizing the safety of the operation.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.