How to Reduce Oil Loss of Oil Tank Breather Valve

Introduction

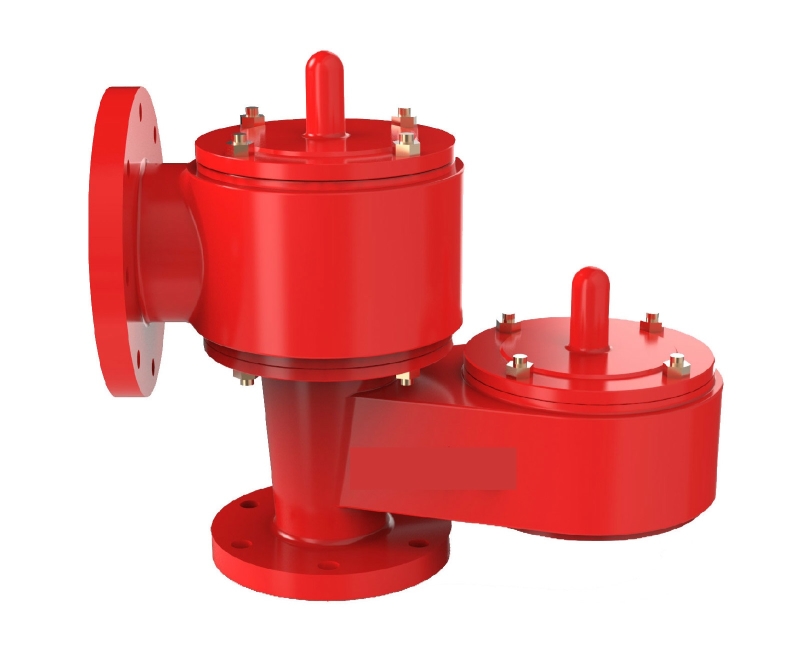

As a specialized oil tank valve, in order to fully play the important role of the oil tank breathing valve, it is necessary to understand the common faults of the oil tank breathing valve, carry out targeted maintenance and repair, prevent safety accidents of the oil tank breathing valve, and ensure that it is always in good condition.

At present, oil tanks are protected by breathing through breathing valves, which can also cause oil loss. This loss has caused significant losses to oil depots and waste of oil resources. If oil vapor can be prevented from being discharged from the breathing valve and collected for utilization, it will bring certain benefits.

Function of the oil tank breathing valve

The oil tank breathing valve on the top of the storage tank provides the maximum and most direct passage for the storage tank to breathe, and reduces the evaporation of oil to ensure the quality of the oil product. The oil tank breathing valve provides breathing channels for oil storage tanks, mainly including the following situations: firstly, due to the large temperature difference between day and night, there is a significant temperature change in the oil storage tank, resulting in small flow breathing; Secondly, during the process of receiving and sending oil from the oil storage tank, the volume of gas in the tank changes, forming a large flow rate of breathing; Thirdly, abnormal weather changes have led to high flow breathing in oil storage tanks. During the high flow breathing process of oil storage tanks, the oil tank breathing valve is mainly used to balance the pressure difference between the inside and outside, and the positive and negative pressure in the oil storage tank is used to regulate the oil tank breathing.

The exhalation and suction of the suction valve continuously increase the oil level in the tank and reduce the internal gas volume when the storage tank is fed. This causes the pressure inside the tank to continuously increase. When the set pressure of the tank’s breathing valve is reached, it jumps to release the pressure.

At the same time, when the oil storage tank is discharged, a negative pressure forms in the tank. At this time, the tank breathing valve opens, and air is sucked in as pressure compensation in the tank. The exhalation and suction of the tank breathing valve can prevent the tank from being compressed or burst due to low or high pressure.

Breather valve fault type

Breather valve faults mainly include rust, freezing, blockage, internal component bonding, and air leakage.

Preventive measure

(1) Select the appropriate type of breathing valve. On the one hand, determine the diameter of the oil tank breathing valve, combined with the breathing valve to reduce static electricity and the hourly oil inlet and outlet flow rate of the storage tank. Select a breathing valve with the appropriate diameter to maintain normal ventilation during the oil inlet and outlet process. For example, a 50mm diameter oil tank breathing valve can receive and send oil flow rate less than 25m3 per hour; A 100mm diameter oil tank breathing valve with an hourly oil flow rate of approximately 30-100m3; A 150mm diameter oil tank breathing valve with an hourly oil flow rate of approximately 101-150m3; 250mm diameter oil tank breathing valve, with an hourly oil flow of over 300m3. On the other hand, determining the control pressure of the oil tank breathing valve, combined with the design pressure and pressure of the oil tank, determines the vacuum degree and control pressure of the oil tank breathing valve. If the service life of the oil tank is long, and combined with the strength of the top of the oil tank, the working pressure of the oil tank breathing valve should be reasonably adjusted. When using the same type of breathing valve for the same oil tank, the working pressure of the breathing valve should be determined based on the minimum pressure value of the oil tank.

(2) To extend the service life of the oil tank breathing valve, daily inspections should be carried out, carefully analyzing the breathing condition and appearance of the oil tank breathing valve, focusing on checking whether there are any abnormalities in the valve body and tank body of the oil tank breathing valve, whether the equipotential bridging connection between the breathing valve and the short pipe or flame arrester is reliable and firm, whether there is air leakage in the oil tank breathing valve, and whether the sealing net is smooth or damaged, Whether the pressure difference of the U-shaped pressure gauge is normal, etc.

(3) Comprehensive and regular maintenance. In addition to daily inspections, it is also necessary to conduct comprehensive and regular maintenance and repair. Generally, the oil tank breathing valve can be comprehensively inspected every six months. For some special situations, the inspection cycle can be appropriately shortened. Carefully check whether the spring, guide hole, guide rod, valve seat, valve disc, etc. of the oil tank breathing valve have accumulated scale or rust, and carefully clean and treat them, For problems such as stuck or unsmooth operation of the valve disc, timely maintenance and repair should be carried out, and the dust and rust on the sealing net should be wiped to ensure that the gas in the oil tank breathing valve can enter and exit smoothly.

(4) Take effective safety measures. During the inspection process, a backup breathing valve should be installed. When installing or disassembling, attention should be paid to balancing the internal and external air pressure of the oil storage tank. Workers should wear explosion-proof equipment and anti-static clothing, handle and disassemble gently, and do not knock. During the maintenance process, it is strictly prohibited to apply lubricating oil to the valve seat, guide hole, or guide rod. The calibration process of the oil tank breathing valve should be carefully recorded, and data should be archived.

Summary

The oil tank breathing valve is an important safety accessory in oil storage tanks, playing a very important role. Considering the common faults of the oil tank breathing valve, effective maintenance measures should be carefully taken to ensure the safe and normal use of the oil tank breathing valve.

By Sun

By Sun