How to solve the problem of high-temperature corrosion and the use of tubing in partial milling wells?

The depth of oil recovery wells in domestic oil wells is getting deeper and deeper, and the downhole temperature exceeds 150°C.

Especially with the development of oil recovery technology and the application of high-temperature steam injection oil recovery technology, the temperature of oil wells can reach 300°C.

As the temperature rises, the chemical corrosion and wear of oil well pipes increase geometrically.

The existing oil pipe protection technology can not meet the production needs, especially the oil wells rich in CO2 and Cl- and the water injection wells containing acid, the corrosion of oil pipes And the wear is more serious.

At present, the most widely used anti-corrosion and anti-wear technologies for tubing are lined with polyethylene tubing and carbonitrided tubing.

Among them, lined with polyethylene can improve the anti-corrosion performance and anti-partial wear performance of the tubing, but its use temperature cannot exceed 95 ℃, when the temperature is too high, the lined polyethylene pipe is easy to swell, and the tensioning force becomes poor, which limits the application of this type of product in high-temperature wells and deep wells.

Although the carbonitriding anticorrosive tubing does not have the problem of tensioning force, but Its anti-corrosion performance and anti-partial wear performance are poor.

In response to this problem, Shengji has developed a high-temperature corrosion-resistant, anti-eccentric wear composite coating tubing, which mainly solves the problem of poor corrosion resistance and wear resistance of existing tubing under high temperature conditions greater than 150 ℃ and well depths exceeding 2500 meters.

Technical problems such as poor bonding force between the wear layer and the tubing body.

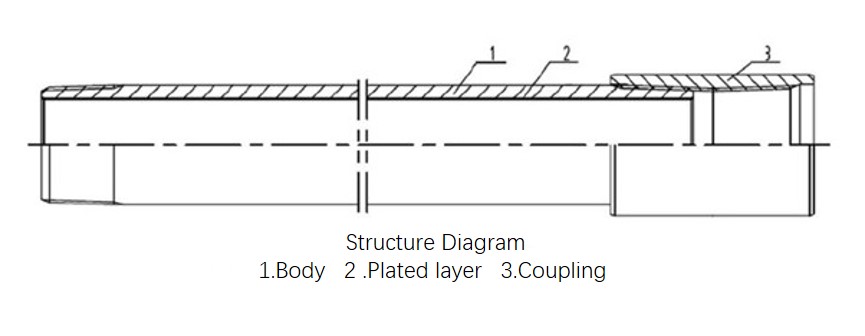

The new product mainly includes a composite coating on the inner wall of the tubing body, coupling, and tubing body.

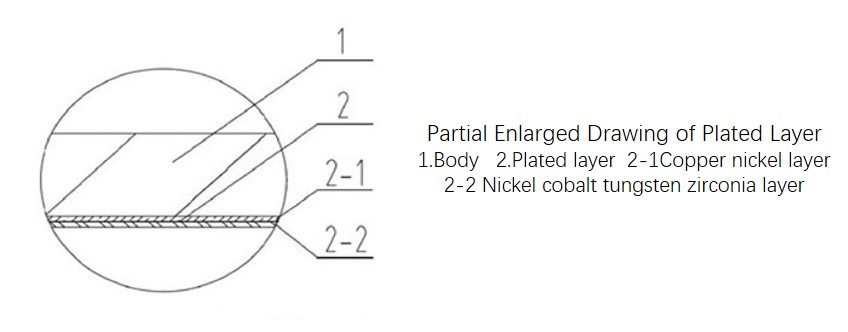

The inner layer of the composite coating is copper-nickel coating, and the outer layer is nickel-cobalt-tungsten-zirconium oxide coating to form a double-layer protective layer.

The thickness of the copper-nickel coating is 0. .01mm~0.02mm, the thickness of the nickel-cobalt-tungsten-zirconia coating is 0.015mm-0.025mm; the copper-nickel coating and the nickel-cobalt-tungsten zirconium oxide coating are completed on the inner wall of the tubing body through a composite plating process.

Structure diagram

1.Body 2 .Plated layer 3.Coupling

Partial enlarged drawing of plated layer

1.Body 2.Plated layer 2-1Copper nickel layer

2-2 Nickel cobalt tungsten zirconia layer

The product includes a tubing body 1, a coupling 3, and a composite coating 2 on the inner wall of the tubing body

1. The composite coating 2 has an inner layer of copper-nickel coating 2-1 and an outer layer of nickel-cobalt-tungsten-zirconia coating 2-2, forming a double layer Protective layer, thickness of copper-nickel coating 2-1 is 0.01mm~0.02mm, thickness of nickel-cobalt-tungsten zirconium oxide coating 2-2 is 0.015mm-0.025mm; copper-nickel coating 2-1, nickel-cobalt-tungsten zirconium oxide coating 2-2 is completed on the inner wall of the tubing body 1 through a composite plating process.

The specific process is: after the tubing body 1 is sandblasted, pickled, and washed with water, the anode is inserted into the inner hole of the tubing body 1 and passed through the pump And the storage tank and other circulation systems, the copper-nickel alloy plating solution is continuously circulated in the tubing body 1 to deposit copper-nickel ions on the inner surface of the tubing body 1 to form a copper-nickel plating layer 2-1, and then After washing with water, the nickel-cobalt-tungsten-zirconium oxide composite plating solution is circulated in the tubing body 1.

Under the state of electricity, nickel, cobalt, tungsten and other metal ions and zirconia fine powder are in the copper-nickel plating layer 2-1 in the tubing body 1.

A second layer of nickel-cobalt-tungsten-zirconia coating 2-2 was deposited on the inner surface.

By controlling the current density and the electroplating time, a copper-nickel coating 2-1 and a nickel-cobalt-tungsten-zirconia coating 2-2 that meet the thickness requirements can be obtained on the inner wall of the oil pipe, and finally a composite coating 2, that is, a double-layer protective layer is formed.

This effectively protects the tubing body.

By Sun

By Sun