Frac Wellhead and Christmas Tree

In the process of oil recovery, multistage fracturing of horizontal wells is currently the most advanced technology in the world, and represents the development direction of oil and gas production technology. Multistage fracturing technology is to strictly control the number, diameter and phase of perforation in several or more horizontal sections with better reservoir along the horizontal well bore, according to the physical properties and the characteristics of the reservoir that several or more horizontal oil layers can be opened at the same time during a fracturing operation. For tight sandstone and shale oil and gas, it can only be recovered by increasing its drainage volume and area. Multistage fracturing technology for horizontal wells is the core technology to achieve this goal and increase the production of a single well.

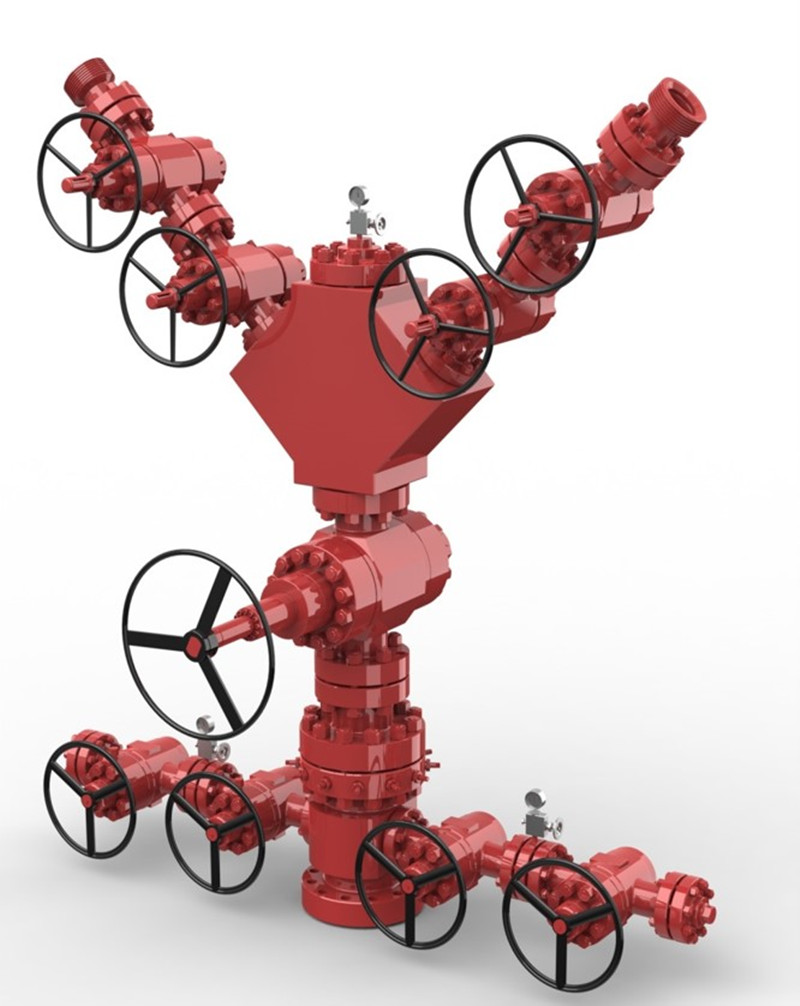

Frac Wellhead and Christmas Tree is used for coiled tubing fracturing and unconventional oil and gas recovery fracture, make a large number of fracture liquid injecting into formation and control the wellhead pressure. Its built to withstand high pressures, up to 20000psi, and fabricated from the most durable components, with its material class meeting HH standards. The fracture wellhead and X-mas tree (fracture head) made by ShengjiPetro has been exported to many renowned oil companies and oil service companies in the USA, Canada, Oman, etc.

Large-scale fracturing and reconstruction are required in the process of exploration and development. The general construction displacement of conventional fracturing is 4-6m3/min, and the construction fluid volume is generally 500-600m3. But the construction displacement of unconventional fracturing is 10-15m3/min, the single-layer fluid consumption is about 2000m3, and the pressure is above 105MPa, which determines that the fracturing wellhead must not only be able to withstand the construction pressure, but also must have a large enough bore. The current commonly used fracturing wellhead devices cannot meet the process requirements of unconventional fracturing with high pressure and large displacement.

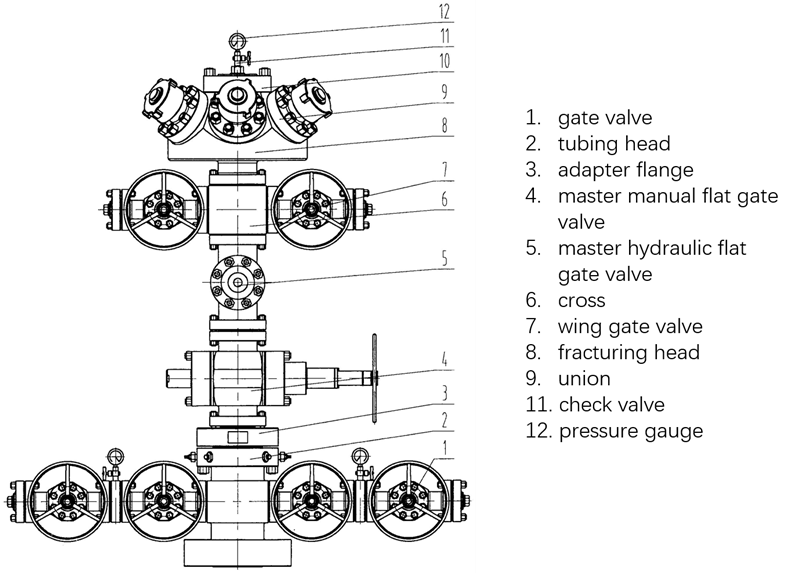

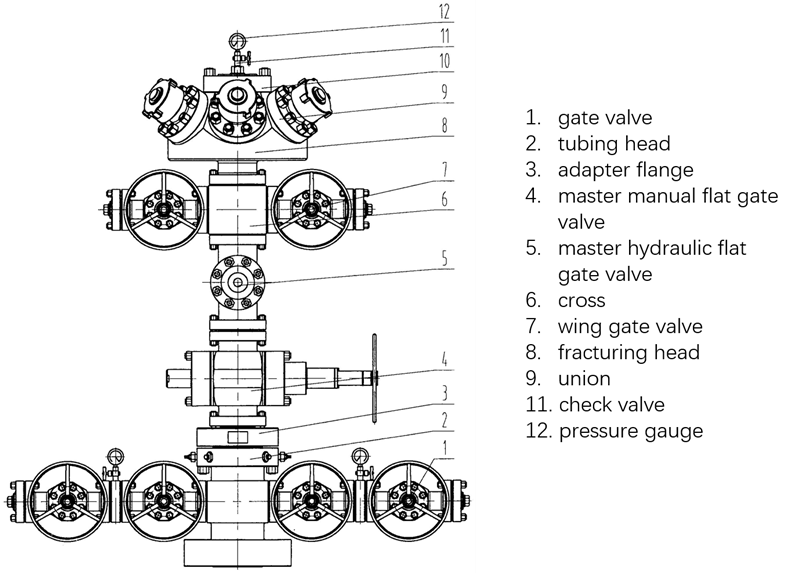

The wellhead structure consists of tubing head gate valve (1), tubing head (2), adapter flange (3), master manual flat gate valve (4), master hydraulic flat gate valve (5), cross (6), wing gate valve (7), fracturing head (8), union (9), check valve (11), pressure gauge (12), etc.。

The stem seal is a high temperature resistant composite seal. There is no leakage under high temperature and high pressure. After thermodynamic calculation, the parts with pressure and load are all reliable and safe under high temperature.

Shengji Petroleum Pumping Unit Manufacturing Plant is one of the main branches of Shengji Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing, maintenance, sales and service of pumping units. The factory has 235 employees, more than 130 sets of various large and medium-sized mechanical processing equipment, fixed assets of 12 million yuan, annual output of 1,200 pumping units, and annual sales income of 200 million yuan.

There are 4 senior engineers, 12 intermediate engineers, 7 assistant engineers, 4 senior technicians and 12 technicians in the pumping unit. Intermediate and senior workers account for more than 90% of all workers. The superb technical level of employees provides a technical guarantee for the production of high-quality pumping units.