Application and Precautions of Back Pressure Valve

Introduction

Back pressure valve, also known as BPV, is an important fluid control valve widely used in various industrial fields, such as petroleum equipment and well control. It can regulate the flow of fluids in a wellhead. Besides ,its design allows fluid to flow in only one direction and prevents fluid from flowing back into the wellhead.

Application

Back pressure valve is a pressure control device that can control the pressure and flow rate of fluids. It is one of the important components commonly used in fluid transmission systems and is widely used in air conditioning, heating, cooling water systems, and other occasions. The working principle of the back pressure valve is to rely on the adjustable spring inside the valve body to achieve pressure control by adjusting the spring force.

When the pressure of the fluid reaches the preset value, the back pressure valve will automatically open, and the fluid will be released through the back pressure valve, causing the pressure to decrease; When the pressure of the fluid is lower than the preset value, the back pressure valve will automatically close, preventing the discharge of the fluid and restoring the pressure to the preset value. The spring force of the back pressure valve can be adjusted by the user to meet different working requirements.

The most critical period during a well completion or workover is the removal of the drilling or workover blowout preventer set or the oil recovery tree. Another critical time during production is when repairs are made while the oil extraction tree is passing through the pressure vessel. In this case, the well must have adequate barriers to protect personnel from injury. In addition, the well must be protected from uncontrolled well surges.

This protection is usually provided by placing barriers in the wellbore. These barriers can be mechanical plugs or plugs used in conjunction with overbalanced fluids. Regardless of the barrier method used, it is standard practice to install a plug or backpressure valve into the wellbore.

Operation Principle

Tubing BPV’s, one way check valves, lock into the tubing suspension to hold pressure from below and allow us to well control or circulate through the pump if required.

Installation

We can set and retrieve these valves by conventional wireline methods where the keys on the lock mandrel, carrying the valve, latch into a landing nipple profile in the tubing hanger. Alternatively, we can install a two-way hanger plug or wellhead back pressure valve (BPV) furnished with ACME threads.

Please kindly noted this is a potentially hazardous operation and should only be carried out by adequately trained personnel.

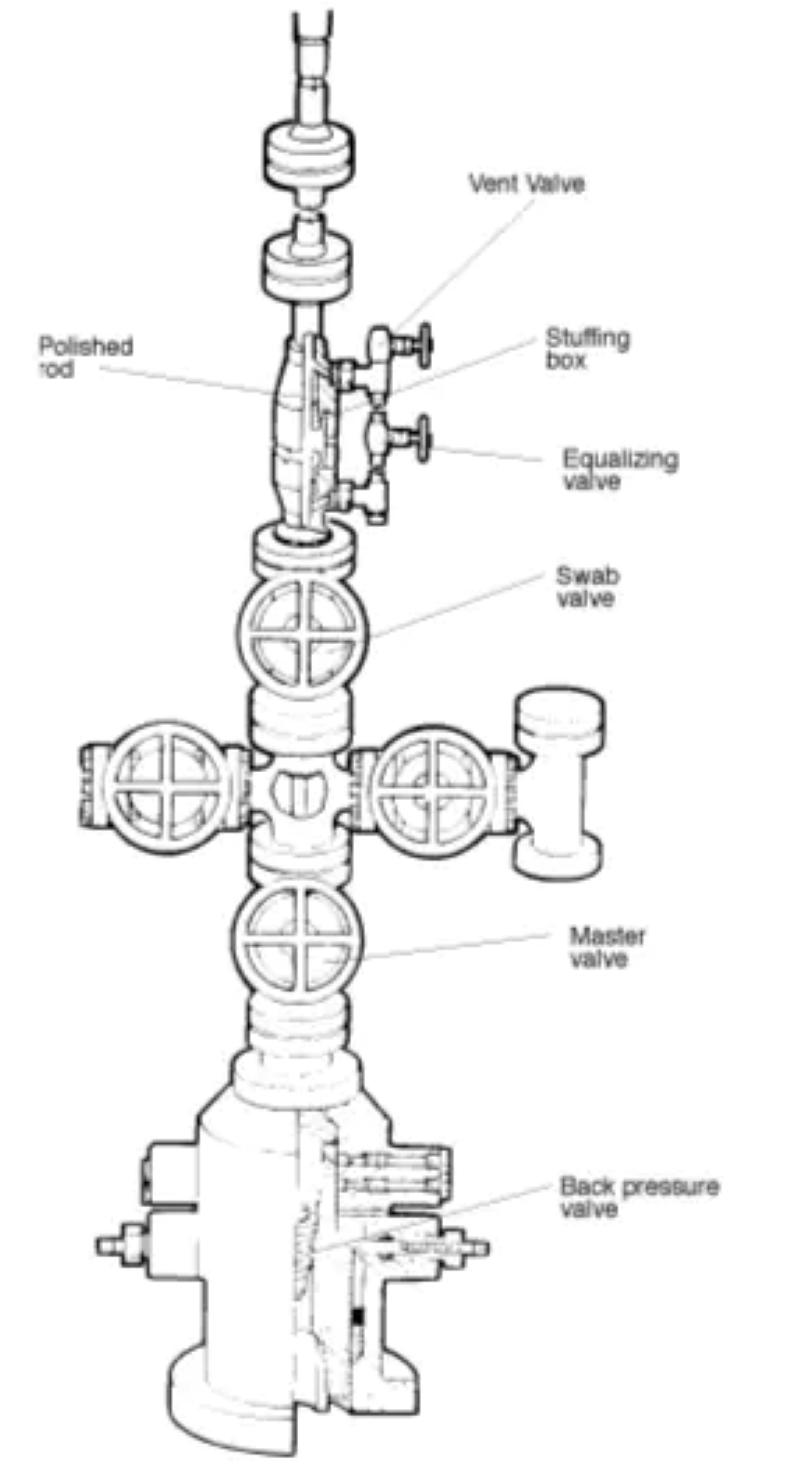

On a live well, we can do this by using a polishing rod and an extraordinary lubricator; see the figure below. Typically, the lubricator consists of two stuffing boxes, a bleeder valve, and a counterbalance valve. After passing the polishing rod through the stuffing box, the BPV is attached to its lower end using an installation/removal tool;. We can then attach the lubricator to the top of the X-mas tree.

By closing the bleeder valve and opening the counterbalance and drawdown valves, any well pressure will act on the top and bottom of the drill pipe, allowing it to be rotated up and down or moved by a friction wrench. We can lower the rod and install the BPV (with left side square threads) by turning it counterclockwise. Further counterclockwise rotation will allow the mounting tool to back off the plug or BPV. Once the installation is complete, we remove the rod from the lubricator. The wellhead back pressure valve (BPV) can be removed by reversing the above procedure.

On dead wells, the plugs may be installed by hand without using the rod lubricator, using either the polished rods or wireline stem to run the plug through the open BOPs or X-mas tree to the tubing hanger. The setting procedure is the same.

Precautions

- Determine the appropriate backpressure valve model and specifications. Different fluids, working pressures, and temperatures require the use of different back pressure valves. When selecting a back pressure valve, it is necessary to choose the appropriate model and specification based on the actual situation.

- Before installing the back pressure valve, it is necessary to clean and exhaust the pipeline. Impurities and gases in the pipeline can affect the normal operation of the back pressure valve, and it is necessary to thoroughly clean and eliminate them before installation.

- Understand the working principle and characteristics of the back pressure valve. Back pressure valve is a valve that controls back pressure in fluid pipelines. Before use, it is necessary to understand its working principle and characteristics to avoid incorrect use.

- The adjustment of the back pressure valve requires a certain amount of time. When using a back pressure valve for fluid regulation, it takes a certain amount of time to reach a stable state. Patience is required during adjustment.

- Regularly inspect and maintain the back pressure valve. The back pressure valve is a mechanical device that requires regular inspection and maintenance to ensure its normal operation and extend its service life.

- Avoid overloading the back pressure valve. When using a back pressure valve, it is necessary to avoid exceeding its rated pressure range, otherwise it may cause overload and damage.

- Avoid backpressure valve leakage. The leakage of the back pressure valve can affect its normal operation and cause energy waste, requiring regular inspection and maintenance to avoid leakage.

- Avoid scaling and blockage of the back pressure valve. When using a back pressure valve, it is necessary to avoid scaling and blockage in the pipeline, otherwise it will affect the normal operation of the back pressure valve and cause blockage of the fluid pipeline.

The use of backpressure valves requires strict adherence to operating procedures, regular inspection and maintenance to ensure their normal operation and extend their service life. At the same time, it is necessary to choose a suitable backpressure valve model and specification based on the actual situation to avoid overload and air leakage.

https://www.youtube.com/watch?v=h90Iqox9hvQ&ab_channel=FOPENGG

By Sun

By Sun