Coiled Tubing Applications of Drilling

Introduction

Coiled tubing drilling (CTD) has developed rapidly since its first operation in 1992. The main motivation for coiled tubing drilling is the presence of large-diameter CT, which makes it easier to deliver hydraulic horsepower underground. This horsepower is essential for wellbore cleaning, transporting rock cuttings in the annulus, and providing power for downhole mud motors. In addition, using heavier and more sustainable tubing helps to provide the necessary weight for drilling and withstand the torque generated by drilling operations (torque and resistance during drilling).

Application method

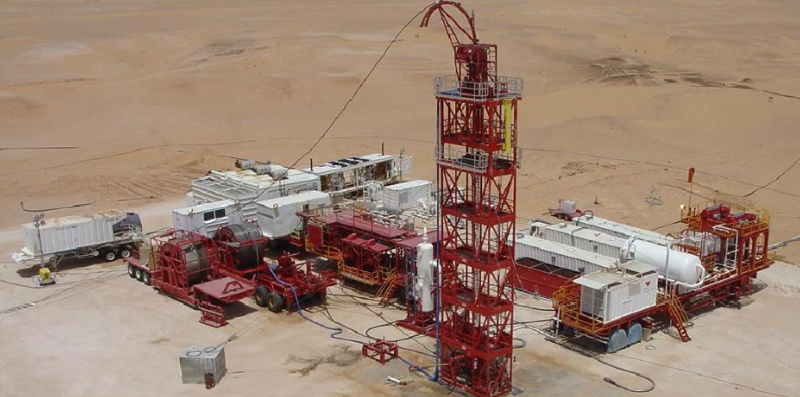

There are several methods for classifying coiled tubing drilling applications. Most operations can be described using the following content (Fig. 1):

Note:

Well status – new or re-entry well

Wellbore trajectory – Sidetracking Drilling or deepening

Well preparation – Retrieving tubing/completion or thru-tubing

Wellbore conditions – overbalanced or underbalanced drilling

From 1991 to 1994 (the figure below shows the global trend of CTD applications), CTD assignments were mainly divided into two categories:

Operations assisted by conventional drilling equipment and techniques.

Operations utilizing the unique capabilities of CT

Nowadays, due to the significant improvement in CTD technology and reliability, the demand for CTD has also greatly increased.

Advantage of Coiled tubing

In drilling operations, coiled tubing has significant advantages in the following aspects.

1.Cost Reduction

An important goal of the early CTD attempts was to reduce costs. The main items that CTD relied on for cost savings were:

Reduced hole sizes (slimmer holes)

Reduced well size

Reduced labour costs

Compared with conventional operation methods, coiled tubing operation has the advantages of cost saving, simplicity, time saving, safety and reliability. It has been widely used in oilfield workovers, drilling, completion, logging, and stimulation operations. The use of coiled tubing operation equipment can greatly reduce drilling rig costs and operation time, and can save 50% to 70% of costs compared to traditional workover operations. Compared with traditional joint tubing strings, coiled tubing has the advantages of saving time in lifting and lowering the tubing string, eliminating the heavy labor of loading and unloading a single string, continuously and flexibly circulating working fluid underground, reducing formation damage, ensuring safety and reliability, high profits, and wider applications.

2.Safety and Environment

Coiled tubing well control equipment is configured to provide a higher level of well surge control than in conventionally drilled wells with drill pipe. This level of control is due to a lower percentage of pipe up and down drilling, handling and tool joint making and breaking. In addition, well surge risk (the cause of well surges in drilling) is not as much of a threat to manpower and equipment as it is in conventional drilling operations due to the adequately controlled well pressures provided by the CT well control equipment.

In addition, drilling noise is reduced by decreasing the wellsite area. The equipment is easier to operate compared to conventional drilling. In addition, operations using Coiled tubing rotating on CT reels cause much less noise pollution than operations using drill pipe.

- Technology

Underbalanced drilling: The safety advantages of CTD are more pronounced in underbalanced drilling, meaning better well control. In addition, underbalanced drilling is used to reduce reservoir damage because it reduces fluid intrusion into the formation, which is often achieved by using CT through production tubing.

Lateral drilling and deepening: CTD offers significant operational and cost advantages over conventional drilling, especially in depleted zones. Ultimately, the techniques and equipment used in CTD will provide a degree of control and responsiveness that will allow “joystick drilling”.

Since cables can also be used to run through the Coiled tubing while drilling up and down, this will give us the opportunity to obtain more realistic data than that transmitted by mud pulses.

In addition, the Coiled tubing also has a shorter start-up and down time, eliminating the need to reconnect or disconnect.

Limitations and Disadvantage

Although coiled tubing has many advantages over conventional tubing, it is not perfect, mainly reflected in the following below.

1.From a financial perspective:

In many areas, the large number of low-cost conventional rigs makes the use of CTD uneconomical for certain applications. In these areas, only specialized CTD techniques that cannot be done with conventional equipment are viable.

CT is more expensive per foot than OCTG. In addition, depending on the drilling operation, it will be necessary to scrap used tubing for CT after six or more starts. In contrast, drill pipe will last longer than this tubing.

2.From a technical perspective:

In some applications, the inability to use higher pumping rates, WOB or torque cancels out the advantage of being able to drill smaller holes. In addition, drilling larger hole sizes can be limited.

Currently, CTD cannot be used for drilling sections and horizontal sections of horizontal and large angle wells.

Since CT tubular columns cannot be rotated, downhole tools (e.g., RSS drilling) must be used

Tubing life is difficult to predict and failures can occur suddenly.

Limited drilling fluid life: in CTD, increasing the solids in the mud is not recommended as it may lead to tubing column corrosion

Limited experience and equipment due to limited dissemination of such techniques except in some areas.

In ultra-balanced drilling, differential pressure increases the chances of differential pressure jamming of the wellbore drilling tool assemblies. This can also occur when drilling in Coiled tubing as the CT is running and there are residual stresses in the CT which will cause buckling sometimes.

Summary

The rapid development of coiled tubing drilling technology is attributed to the following factors: the coiled tubing industry has reached a mature stage of providing necessary equipment and basic technology; Coiled tubing drilling technology is competitive in the market, sometimes even gaining the upper hand; Having a technological advantage in directional drilling and underbalanced drilling; The oil and gas industry has gained a greater understanding of the capabilities and limitations of coiled tubing drilling, enabling a more reasonable selection of drilling targets, ultimately resulting in a higher success rate for coiled tubing drilling.

In recent years, the number of coiled tubing drilling operations has reached 900-1000 per year, of which about 120 directional wells are sidetracked in old wells and about 800 shallow vertical wells are newly drilled. Coiled tubing drilling technology has become an important technology for economically and efficiently deepening drilling, sidetracking old wells, and drilling shallow wells in various oil and gas reservoirs. It has won a position in the drilling market, especially in the underbalanced horizontal drilling market.

By Sun

By Sun