Types and processes of drilling processes

Drilling plays a very important role in the tasks of oil exploration and oil field development.

For example, finding and confirming oil-bearing structures, obtaining industrial oil flows, discovering the oil-bearing area and reserves of proven oil-bearing structures, obtaining geological information and development data about oilfields, and finally taking crude oil from the ground to the surface, etc., are all completed by drilling. Drilling is an important part of the exploration and exploitation of oil and gas resources,

and an important means of exploration and development of oil.

- The types of drilling can be divided into the following types.

(1) Reference well: In the regional census stage, the well is drilled in order to understand the sedimentary characteristics and oil and gas bearing of the formation, verify the geophysical results, and provide geophysical parameters. Generally, bedrock is drilled and full well coring is required.

(2) Profile wells: wells drilled along a large regional profile in the coverage area. The purpose is to uncover regional geological profiles, study stratigraphic lithology, lithofacies changes and find structures. It is mainly used in the regional census stage.

(3) Parameter wells: in the oil-bearing basin, in order to understand the regional structure, provide the wells drilled with rock physical parameters, and the parameter wells are mainly used in the comprehensive detailed investigation stage.

(4) Structural well: In order to compile the structural map of a standard layer underground, understand its geological structural characteristics, and verify the wells drilled by geophysical prospecting results.

(5) Exploration wells: wells drilled to determine the existence of oil and gas reservoirs, delimit the boundaries of oil and gas reservoirs, and conduct industrial evaluation of oil and gas reservoirs and obtain geological data required for oil and gas development within the scope of favorable oil and gas collection structures or oil and gas fields. The wells drilled at each exploration stage can be divided into pre-exploration wells, preliminary exploration wells, detailed exploration wells, etc.

(6) Data wells: wells drilled for the purpose of preparing oil and gas field development plans, or obtaining data for certain thematic studies during the development process.

(7) Production wells: Wells drilled for the purpose of extracting oil and gas when developing oil fields. Production wells can be divided into oil producing wells and gas producing wells.

(8) Water injection (gas) wells: wells drilled by water injection and gas injection in the oilfield to supplement and rationally use formation energy in order to improve recovery and development speed. Wells drilled specifically for water and gas injection are called injection wells or gas injection wells, and are sometimes collectively referred to as injection wells.

(9) Inspection well: the well drilled in order to find out the pressure of each oil layer, the distribution of oil, gas and water, the distribution and change of the residual oil saturation, and the effect of various adjustment and potential mining measures when the oilfield is developed to a certain water-cutting stage.

(10) Observation wells: wells specially used to understand the underground dynamics of oilfields during oilfield development. Such as observing the pressure of various oil layers, the law of water content change and the law of single-layer flooding! It generally does not bear production tasks.

(11) Adjustment wells: In the middle and late stages of oilfield development, adjust the wells drilled in the original development well network (including production wells, injection wells, observation wells, etc.) in order to further improve the development effect and final recovery rate. The production layer pressure of such wells is either low pressure due to the later stages of oil recovery or high pressure due to the energy held by the injection well.

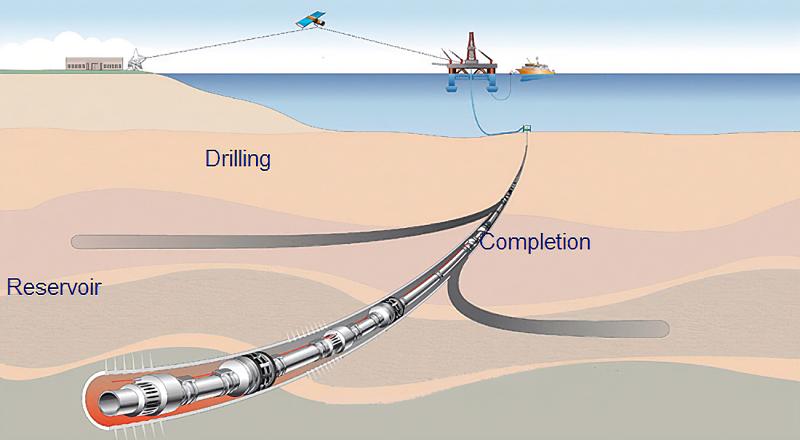

- Drilling construction process

(1) Pre-drilling operations

The main task of pre-drilling operations is to prepare drilling conditions. The main work of pre-drilling operations includes: building drilling equipment such as simple highway handling derricks, leveling the well site installation derricks, and preparing drilling water and equipment.

(2) Drill the surface

Surface strata are generally soft and must be specially reinforced after drilling before continuing to drill deep. This reinforcement is generally accomplished by injecting a large-sized surface casing and cementing the casing with the formation (called cementing) with cement. Therefore, when drilling surface formations, large-size drill bits must be used, and the drilling depth is appropriate (too shallow, the soft formation is not well reinforced to affect subsequent drilling, too deep will increase the cost and cause waste, generally about 20 meters to 1200 meters). After drilling into the hard formation, the lower casing solidifies the surface layer, and then continues to drill after the cementing cement solidifies.

(3) Drilling into the target layer

Once the surface layer is solidified, a drill bit of a certain size smaller than the first opening is used to drill deep into the formation. At this time, it is generally necessary to continuously enroll geological data and encrypt the relevant geological data when needed or in the required well section to solve the related needs of geological research and drilling engineering. Before drilling the target layer, when encountering some special conditions such as collapseable layer, high-yield water layer, abnormal high pressure (or low pressure) layer and other layers that are difficult to control during drilling, it is also necessary to enter the technical casing cementing, and then use a smaller drill bit than “two openings” to drill into the target layer (commonly known as “three openings”). After drilling the target layer, it is generally necessary to carry out the data acquisition of many special requirements projects (such as core extraction, logging, etc.).

(4) Midway test

Some exploration wells may find good oil and gas display before drilling to the design target layer, at which time the drilling can be stopped as needed, and the drill pipe can be used as a conduit for the flow of formation fluid from the bottom of the well to the wellhead, and the main purpose of testing is to confirm the oil content and productivity of the formation. This is the midway test, and you usually have to continue drilling after the halfway test.

(5) Completion electrical measurement

In the process of exploration drilling, if valuable oil and gas reservoirs are found, logging that needs to be carried out at any time can be arranged at any time according to the specific situation, but this situation is generally rare, and if it is not particularly urgent or important, it is generally arranged to conduct electrical measurements together with other important layers at the final drilling. When a well is completed, a systematic and comprehensive logging is generally carried out to obtain electrical measurement data for multiple projects of the well. This type of logging, called completion electrical measurement, distinguishes it from other logs. Completion electrical measurement can obtain the logging data of each layer of the whole well, which is of great significance for the detailed division and comparison of the downhole strata, the understanding of the lithology and oil and gas properties of the target layer, etc., and it is an important data that must be admitted in the drilling.

(6) Cementing and completion

The borehole that has been drilled is reinforced with the wellbore, which is called cementing. The operation of drilling the target layer and establishing the connection method between the target layer and the wellbore is called completion. The purpose of completion is twofold: first, to establish a channel to ensure the smooth flow of oil and gas from the formation to the wellbore; The second is to strengthen the well wall of the oil layer.

Completion engineering refers to the engineering stage from the depth of completion to the handover. There are four completion methods:

Open-hole completion: refers to the completion method of uncasing sealing of well sections in oil and gas layers;

Perforated completion: refers to the completion method of drilling through the oil and gas layer, passing the oil layer casing down to the bottom of the oil and gas layer, cementing the sealing oil and gas layer, and then using the perforator to shoot through the casing and cement ring of the well section of the oil and gas layer to form a channel in which oil and gas flow into the well.

Through-hole completion: It is a completion method in which the borehole (or slit) casing with holes is drilled through the oil and gas layer to the bottom of the oil and gas layer, and the wellbore above the oil and gas layer is filled with cement sealing.

Lining completion: It is a completion method that drills to the top of the oil and gas layer, casing the lower oil layer, injects cement to seal, and then uses a small drill bit to drill through the oil and gas layer, and enters the liner with holes (or cuts).

By Sun

By Sun